The OTL1200-1200-1200-1200 three temperature zone tube furnace has three heating zones, using a double-layer shell structure and electronic control temperature instruments. Each heating zone can be controlled by 30 stages of program temperature control, phase-shift triggering, and thyristor control. The furnace is made of alumina polycrystalline fiber material, and stainless steel flanges are installed at both ends of the furnace tube. The stainless steel flange is equipped with gas nozzles, valves, and pressure gauges. When vacuuming, the vacuum degree can reach 10-3 Pa. The OTL1200-1200-1200 is horizontal, and the three temperature zones can be independently controlled and set to different temperatures. It is easy to use and operate. The OTL1200-1200-1200 three temperature zone tube furnace has the advantages of temperature field balance, low surface temperature, fast temperature rise and fall rate, energy saving, etc. It is a popular choice among universities. Ideal products for high-temperature atmosphere sintering, atmosphere reduction, CVD experiments, and vacuum annealing in research institutes and industrial and mining enterprises

| model | Power kw | Furnace tube size mm | supply voltage | Number of phases |

| OTL1200-1200-1200-60 | 3 | φ60*1300 | 220V | single phase |

| OTL1200-1200-1200-80 | 3 | φ80*1300 | 220V | single phase |

| OTL1200-1200-1200-100 | 4 | φ100*1300 | 220V | single phase |

| OTL1200-1200-1200-150 | 4 | φ150*1300 | 220V | single phase |

(3) Good resistance balance and temperature field balance

(4) Heating element: Kanthal A1 imported resistance wire from Sweden (resistance wire can be guaranteed for 2 years)

When the circuit experiences overcurrent or leakage, the circuit will automatically disconnect

The furnace is equipped with communication interfaces and software, which can directly control various parameters of the furnace through a computer, and observe the PV and SV temperature values and instrument operation on the furnace from the computer. The actual heating curve of the furnace will be drawn in real time by the computer, and the temperature data at each moment can be saved, and the vacuum degree can be adjusted at any time.

(2) Adopting Japanese technology for molding.

(3) The spacing and pitch of the resistance wires in the furnace are all arranged according to the best thermal technology in Japan, and the temperature field is simulated through thermal software

(4) Using 4-week heating, the temperature field is more balanced

(All imported electrical appliances certified by UL)

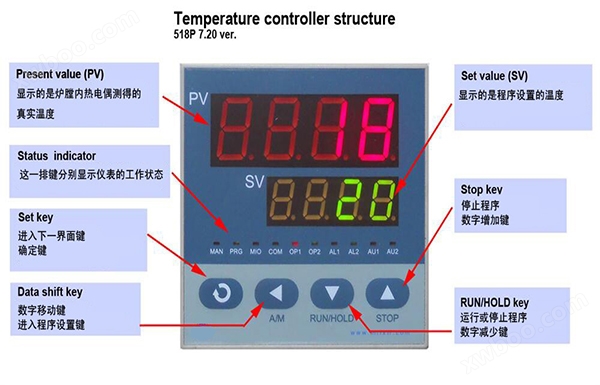

Adopting Yudian program temperature control instrument (standard)